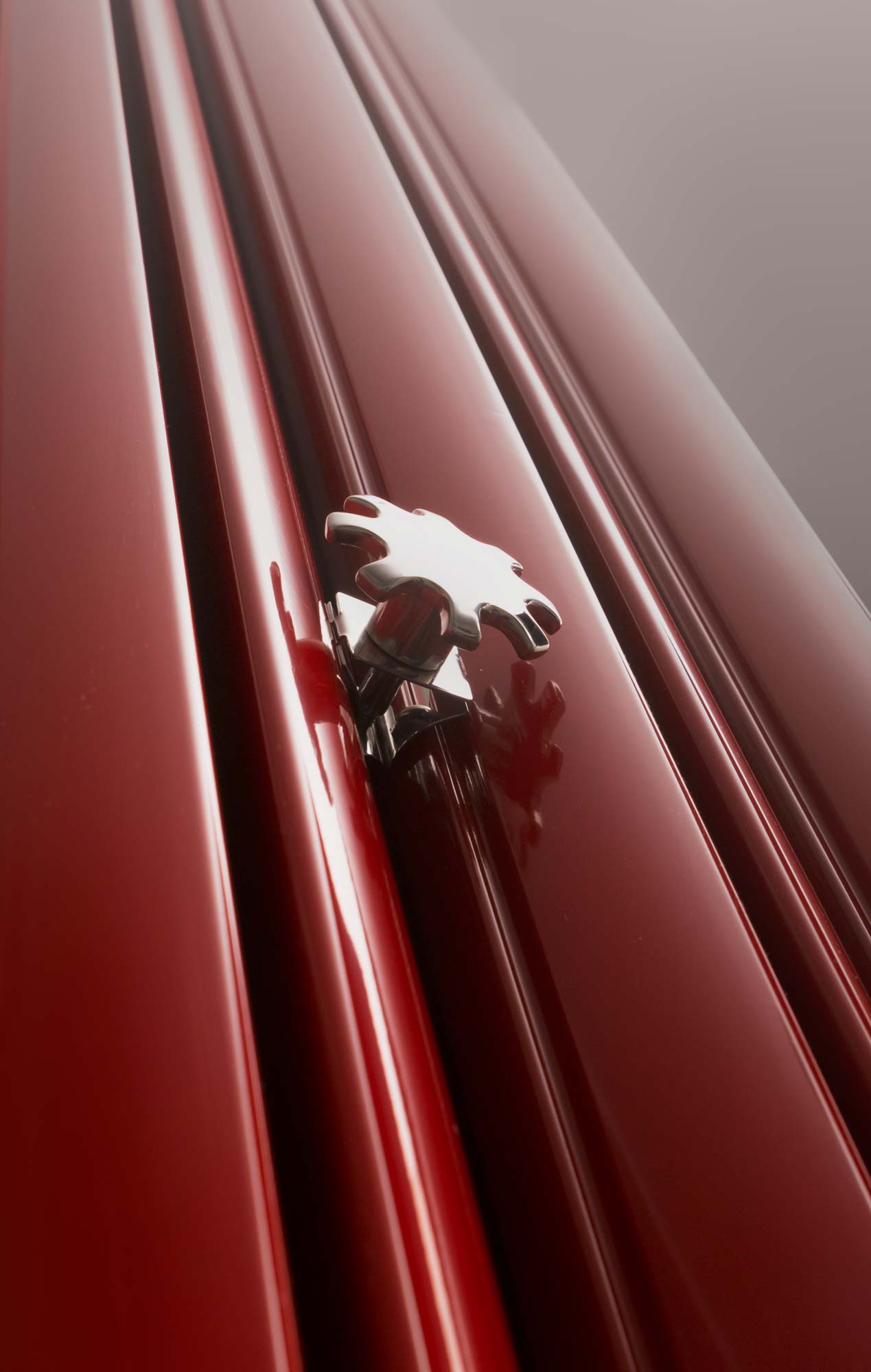

Grzejniki

Świetnie zaprojektowane, funkcjonalne i jakie tylko zechcesz. Idealnie podkreślą charakter Twojego wnętrza i nadadzą nowego piękna domowemu ciepłu.

Zobacz grzejniki

Świetnie zaprojektowane, funkcjonalne i jakie tylko zechcesz. Idealnie podkreślą charakter Twojego wnętrza i nadadzą nowego piękna domowemu ciepłu.

Zobacz grzejniki

Nowoczesne i proste w obsłudze. Pozwolą Ci precyzyjnie regulować zużycie energii i równomiernie ogrzeją wnętrze z pomocą indywidualnego termostatu.

Zobacz grzejniki elektryczne

Uniwersalne, niezawodnie i zaprojektowane dla Twojej wygody. Zapewnią domowe ciepło dokładnie tam, gdzie chcesz i kiedy chcesz.

Zobacz grzałki

Ułatwią i usprawnią korzystanie z naszych grzejników – abyś mógł cieszyć się domowym ciepłem w każdym wnętrzu.

Zobacz akcesoria

Nieustannie od 30 lat projektujemy i tworzymy innowacyjne rozwiązania w zakresie techniki grzewczej. Z każdym produktem oferujemy jakość i design, których nie sposób znaleźć nigdzie indziej.

Zapraszamy do zapoznania się ze zaktualizowanym cennikiem grzejników ENIX.

Nowy cennik grzejników płytowych obowiązuje od 1.07.2022.

Funkcjonalność, estetyka i wysoka jakość to cechy, do których przykładamy szczególną uwagę w naszych produktach. Ciepło to nie tylko optymalna temperatura, ale i odpowiednio stworzony klimat. Z naszymi nowoczesnymi grzejnikami dekoracyjnymi i akcesoriami stworzysz niepowtarzalną atmosferę w swoich wnętrzach – poznaj designerskie projekty Enix.

W naszej ofercie znajdują się grzejniki tradycyjne i elektryczne stworzone z myślą o najbardziej wymagających użytkownikach. Klasyczne grzejniki drabinkowe, żeberkowe i płytowe dostępne są w wersji zarówno horyzontalnej, jak i wertykalnej. Nienachalny, acz przemyślany design w połączeniu z wysoką jakością wykonania wpasuje się w każde wnętrze.

Minimalistyczne, o nietuzinkowym kształcie grzejniki uzupełnią nowoczesne aranżacje, same w sobie stając się niesztampową dekoracją. Z kolei grzejniki artystyczne, łączące sztukę i funkcjonalność wprowadzą w pomieszczenia nie tylko ciepło, ale i przeobrażą się w samodzielne dzieło sztuki.

Oferowane przez nas grzałki to praktyczne urządzenia, w których każdy szczegół został z rozmysłem zaprojektowany, by podnieść wygodę użytkowników. Grzałki zapewniają regulowane ciepło niezależnie od pory roku (również poza sezonem grzewczym). Mają ponadczasowy design, są intuicyjne w obsłudze i łatwe do utrzymania w czystości.

Naszą ofertę uzupełniliśmy również o praktyczne akcesoria. Designerskie wieszaki do grzejników doskonale wzbogacają wnętrze. Stanowią nie tylko oryginalne uzupełnienie dostępnych u nas grzejników, ale również poszerzają funkcjonalność pomieszczeń. Powieszony na ozdobnym wieszaku mokry materiał szybko straci swoją wilgoć.

Oferujemy oryginalne zawory, złączki do zaworów i zestawy armatury przyłączeniowej, koniecznych elementów dla korzystania z grzejników. Poza wygodą użytkowania, każdy z elementów wyróżnia się oryginalnym wzornictwem, które doskonale urozmaici wystrój pomieszczenia.

Sprawdź naszą ofertę i zapewnij ciepło i piękno w swojej przestrzeni!